Manupilating Light

Optical Mould Inserts, Plastic Lenses & Mirror Finished Metal Parts

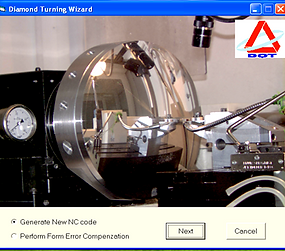

Diamond

Turning Expert

Adaptive application develops free-form tool-path for diamond turning & diamond scribing.

Generates complex free-from profiles for lens array with sharp, jagged-free transition edges on adjacent optical surfaces.

Adaptive Free-form Optical Profile Generation Software

DT-2F-CAM

Diamond Cutter Re-furbishing Machine

Driven with an air-bearing motor.

Promotes chemical change of the diamond cutter when in contact with the wear plate.

Eliminates cutter downtime for sharpening.

Computer Simulated Thermal Shrinkage Compensation for Optical Profile using DT-2F-CAM

Propriety diamond cut software, proven methodology.

Offset shrinkage of plastic optics during molding process.

High form accuracy of the molded lens.

Rapid mold-tool qualification achieving over 90% “first-test-success” rate.

Diamond-Direct-Cut on Hardened Steel

-

No nickel plating required

-

Optical surface with 50 HRc steel

-

High scratch & chipping resistance

-

High mould working temperature >350°C

-

Long mould life (>3x of nickle plated)

-

Less than 8nm Ra mirror surface finish

State-of-the-Art Diamond Machining

&

Plastic Lens Moulding

Plastic Lens Moulding

-

Nano Finishing

-

100% Inspection

-

Material

-

Freeform curves